Written by Barkman Concrete Published on September 21st, 2021

FEATURES

· 15 unique shapes replicate large, irregular flagstone with natural stone texture

· Fast installations with easy-to-install pattern

· Uniform thickness to create comfortable end result

· High strength concrete means long term durability

· Multiple natural color blends available

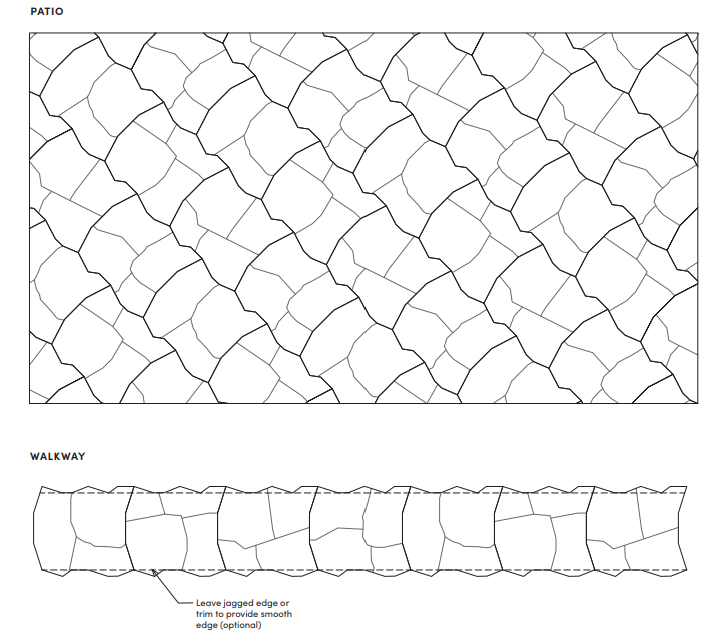

PATTERNS

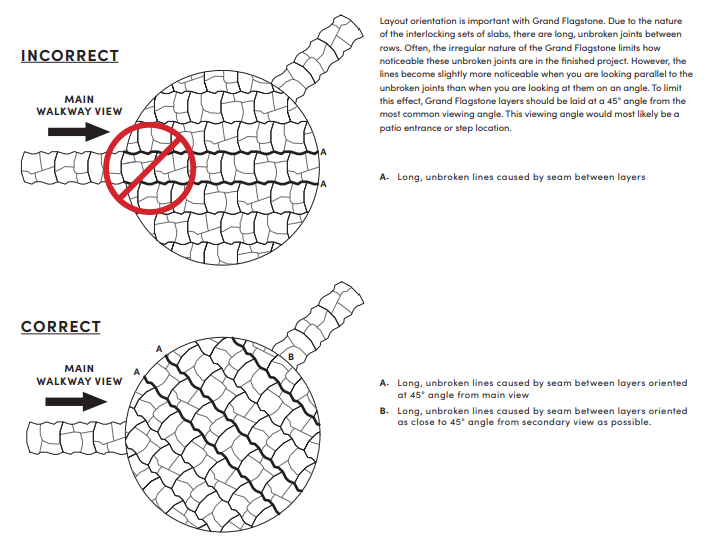

LAYOUT ORIENTATION

PROCEDURE FOR INSTALLING CRACKED PIECES

· Trim broken edges if needed

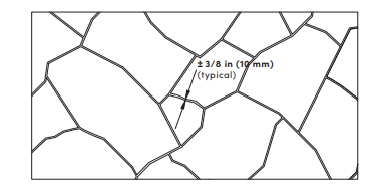

· Install pieces with typical 3/8 in (10 mm) join

Individual pieces of Grand Flagstone can crack either during delivery to the job or during on-site handling prior to placement. Typically less than 5% of the pieces will crack. There are two methods to deal with cracked pieces.

The first method is to use the cracked pieces to fill in around the perimeter of the project where there is always a need for small pieces.

The second method is to use the cracked pieces to enhance the layout pattern. Since Grand Flagstone is designed to create an irregular flagstone walking surface, an extra crack simply provides another joint line in the Grand Flagstone pattern. Place the cracked pieces next to each other with a 3/8 in (10 mm) joint between them. The joint is filled with polymeric jointing sand just like all the other joints. If necessary, the cracked pieces may need to be trimmed to create a smoother edge or provide a larger joint to match all the other joints in your project.

INSTALLATION GUIDE

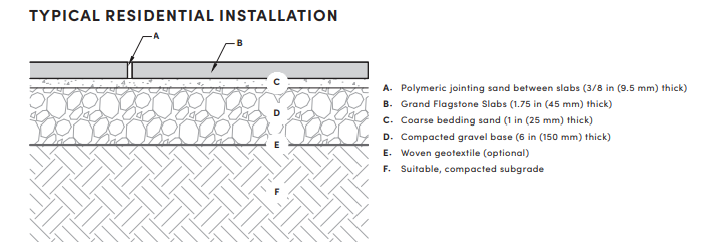

BEDDING SAND INSTALLATION

Using screed rails on the compacted granular base, apply bedding sand at a maximum thickness of 1 in (25 mm). By using a screed board along the top of the screed rails, the bedding sand will level evenly. Bedding sand should be compacted since Grand Flagstone slabs should not be

compacted after installation.

FLAGSTONE INSTALLATION

· Begin by laying the individual pieces of Grand Flagstone on the screeded bedding material according to your detailed project plan.

· Separate individual pieces approximately 3/8 in (10 mm) from each other. When units are set with a 3/8 in (10 mm) gap, a full pallet will produce 90 sq ft (8.36 sq m) of coverage.

· Cut units as needed to finish edges.

· Note: To ensure proper color distribution, mix layers from several bundles at one time.

JOINT SAND INSTALLATION

Once the flagstone pieces are installed, fill all joints with jointing sand suitable for large joints. Sweep the sand into the joints between flagstones until the joints are completely filled. Follow the jointing sand manufacturer’s recommendations for wetting the sand. You may need to repeat this process with more dry sand in a few days to completely fill the joints between individual slabs.

CAUTION: Grand Flagstone slabs should not be compacted after installation.

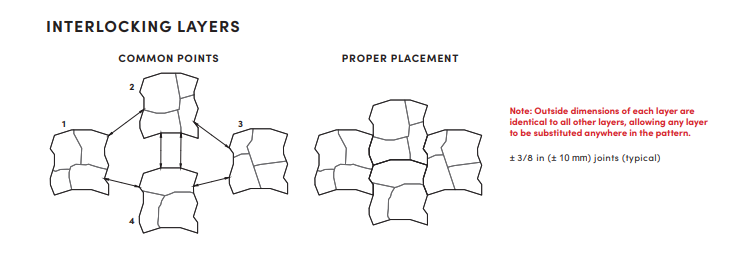

INTERLOCKING LAYERS

Grand Flagstone has been designed so each layer of slabs on a pallet is an interlocking set. Each interlocking set, or layer, of slabs has been designed to interlock with all other layers.

OTHER CONSIDERATIONS

You may want to apply a sealer to protect the flagstone slabs from spills and stains. Always use a high quality sealer specifically formulated for wet-cast concrete.

Not suitable for vehicular traffic

GENERAL NOTES FOR DETAILS

• Final designs for construction must be prepared by a registered professional engineer using the actual conditions of the proposed site and loads.

• Block size and placement shown are for reference only, individual blocks vary with installation pattern.

• Section shown is the minimum recommendation for pedestrian loading. Projects with heavier traffic or sites with poor soil conditions may require thicker gravel base, concrete curb edge restraint, and/or sand subbase.

• Provide adequate surface drainage to prevent ponded water.