Written by Peegy Ontong Published on May 6th, 2022

This post was updated on May 6, 2022.

Applying polymeric sand is one of the last steps in installing a patio or path and comes after all the paving stones have been laid. Polymeric sand is designed to fill the gaps between pavers to keep them solidly in place, prevent weed growth, and allow for proper drainage from the patio. This step finishes your project and will allow you to finally use the space you’ve spent so much energy building. But you might be wondering what is so special about polymeric sand and why you can’t use normal sand for this stage of the process? While regular sand can be used, polymeric sand is better in every way.

Easy Application

Polymeric sand is better than normal sand in its application for one main reason — it’s designed to be easy. Polymeric sand is engineered with lubricants that bind to the individual sand granules, making pouring and sweeping the sand an easy process. This lubricant also allows the sand to settle more deeply between the joints in your patio, making sure that it will not be washed out or blown out.

Prevents Weed Growth, Manage Drainage and Keeps Patio from Shifting

Applying any sand to your patio will grant you benefits such as preventing weed growth, managing drainage, and keeping the patio or path from shifting. However, polymeric sand beats normal sand in each of these benefits due to its setting qualities. Along with lubricant, polymeric sand is also engineered with an adhesive binding agent that is activated upon getting wet. This means that when you water your patio down after applying all the sand, the polymeric sand will settle, bind with itself, and turn into a concrete-like substance. This is excellent in preventing weed growth, as weeds cannot permeate through the hardened sand. This quality also is very helpful in keeping the patio from shifting and despite the polymeric sand’s hardening qualities, it is still designed to manage drainage excellently, which will prevent flooding on your patio or path.

Rigorous Testing to Meet Standards

As a leading manufacturer of polymeric sand products, Polybind is committed to ensuring that it continues to provide the best performing polymeric sand for the hardscape industry. The Polybind production process employs extensive testing during the manufacturing and laboratory phases, as well as conducting field tests. Samples of polymeric sand are collected from each production run and put through an aggressive series of tests in the laboratory to ensure that each batch meets the following standards and characteristics:

ASTM C-144: Gradation for optimum joint density

Tensile Strength: The ability to elongate without rupture on a vehicular application

Compressive Strength: The ability to compress without rupture on a vehicular application

Setup Time: Guaranteed one hour (Rainproof Time)

Setup Temperature: Product works above freezing temperature (18°C)

Flexibility: Product must have ability to withstand freeze/thaw cycles and pavement movement without cracking

Self-Healing: Product must be able to self-heal should minor cracking occur

Durability: Product must withstand all weather elements in extreme conditions so as to qualify for our 15-year Warranty, the most aggressive in the industry.

The ultimate test is the erosion test. A heavy one-hour rain event is simulated after a 24 hours polymeric sand installation. The Polybind polymeric sand must pass this test with all sand remaining in the Petri dish. Benchmark testing has shown that many other competitive products will completely wash out or swell under identical conditions.

Superior Aesthetics

Finally, polymeric sand simply looks better than sand. It comes in four beautiful colors, (Nevada Tan, Oxford Grey, Ivory White, and Jet Black), allowing you to match the sand to the design of your patio. This allows the sand to either pop as an accent colour or is a subtle buffer between pavers. Polymeric sand is also superior to normal sand aside from aesthetics is its longevity. Normal sand will last a while but eventually, it will blow or wash out with the rain and wind, which will leave space for dirt, moss, and weeds to fill in the gaps. Polymeric sand, on the other hand, sets and becomes hard, ensuring your patio looks great for much longer.

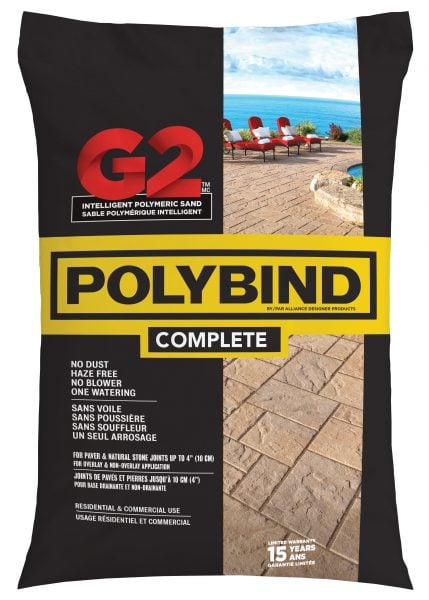

Available through your local landscape dealers is our recommended polymeric sand, Polybind Complete G2, which is made with a state-of-the-art manufacturing process. Specifically, calibrated sand is mixed with sophisticated intelligent polymers which neutralize haze and dust. No blower is needed and the intelligent polymeric sand requires only one watering. Polybind Complete G2 sand is recommended for a variety of uses including pool deck, patios, footpaths, driveways, parking spaces, pavements, etc. It’s available in Nevada Tan, Oxford Grey, Ivory White, and Jet Black.

Normal sand works for patios and paths and can last a while, but it doesn’t stand a chance in competing with the superiority of polymeric sand. Its ease of installation, various benefits, and aesthetic qualities all make for a far better product to use with your patio or path. So, the next time you ask yourself if you can use regular sand, think twice and go for polymeric sand instead.